Services

New Screws

Precision Feedscrews is equipped with machinery to manufacture screw diameters from 35 mm to fifteen inches.

Length capacity is well over 300 inches for one-piece screws. However, we have manufactured two-piece screws over 400 inches in total length.

We have a wide variety of base materials, hard surfacings, platings, coatings, and heat treatments to choose from for your new screw. Precision Feedscrews has more than 30 years experience in cutting the most complicated feedscrew designs in the industry.

Screw Repair

If done properly, a rebuilt screw should be as good as a new screw. That philosophy goes into every screw we rebuild at Precision Feedscrews. To maintain and extend the life of a screw, care must be taken to ensure proper welding procedures are followed. In other words, we don’t take shortcuts! Care must be exercised to maintain concentricity between the outer diameter and the root of the screw.

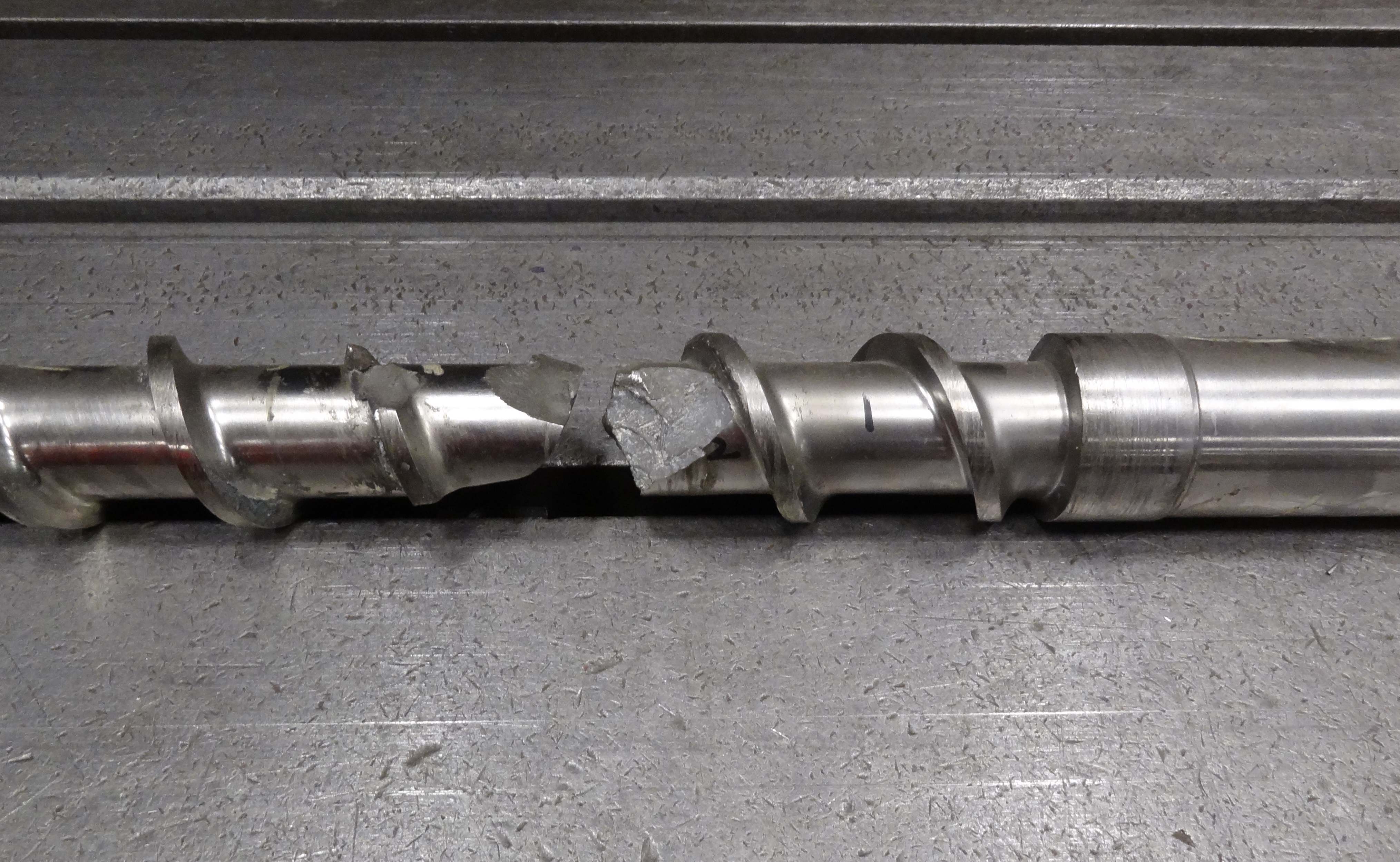

Extra attention is given to specially designed screws and their mixing sections throughout the rebuild process. There is almost no limit to the amount of times a screw can be rebuilt if proper procedures are followed. Our specially developed welding techniques allow us to repair broken flights, damaged mixers, replace worn or damaged drive splines, and repair broken screws.

Whatever your repair needs are, no matter how big or small, Precision Feedscrews can help.

Emergency Repair

As an added service, we offer emergency repair.

Broken screw? Emergency repair needed? We are willing to work continuously on your job until it is completed, giving you the fastest delivery time possible. Delivery time depends on the specific work needed.

A surcharge will be applied to all emergency repairs.

Screw Re-Cuts

Do you have a screw that isn’t performing as expected? Have you made adjustments to your original design?

In addition to rebuilding the flight OD, we can also recut your screw.

Shorten or lengthen feed sections, transitions, or meterings? Add or remove mixers and lengthen or shorten feedscrews? If a re-design and re-cut is what you need, we can do it!

Industrial Hard Chrome

We offer Chrome Plating for surface protection, dimension build up, and super finishing, all within our organization.

We also Super Polish and Chrome Plate to accommodate food-grade applications.

High Wear Solutions

Precision Feedscrews specializes in solving your wear problems. We offer a wide variety of hard surfacing materials, coatings, and base metal encapsulation. Our goal is to provide solutions that best fit your needs.

Outer Diameter Welding

We offer Colmonoy® 56, 57, 83, and 88 and Stellite® 1, 6, and 12 for both new and rebuilt outer diameter surfaces. Welding is done with automatic Plasma Transferred Arc Welders to provide a weld of the highest integrity and minimal cracking. We also utilize MIG and TIG welding for repairs to damaged feedscrews.

Root Encapsulation

We can encapsulate the screw root with hard surfacing where needed to reduce wear. Several different materials are available for this purpose depending upon the need and specific situation.

Coatings

We work with many companies to provide coatings that protect against wear. We also offer industrial hard chrome plating and electroless nickel plating.